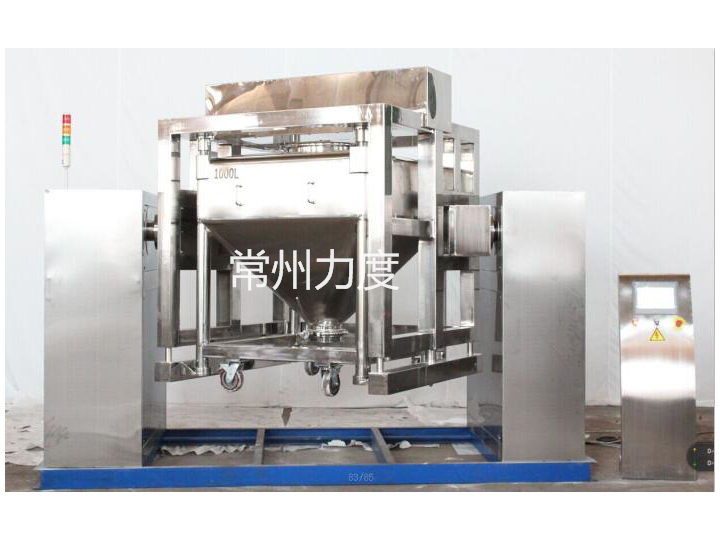

應用概述:

★該機具有自動提升,混合,下降等功能。配一臺料斗混合機及多個不同規格的混合料斗,就能滿足多品種不同批量的混合要求,是藥廠總混的理想設備。同時在制藥、化工、食品等行業廣泛使用

*This equipment can execute automatically raising, blending and lowering tasks. One main machine can be configured with multi-bins so variety blending can be satisfied, consequently it is considered as the ideal blending equipment in pharmaceutical Industry. It is alsoidely used in chemical, foodstuff industries, etc

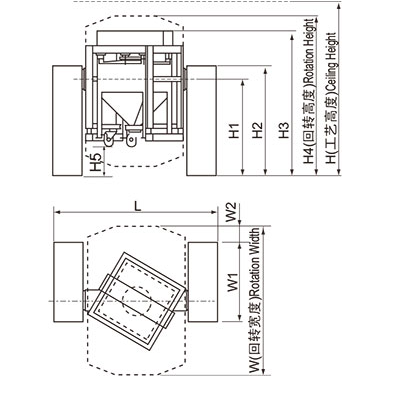

設備外形圖:

技術參數:

| 項目ltem 規格Specification | HZD- 400 | HZD- 400A | HZD- 600 | HZD- 600A | HZD- 800 | HZD- 800A | HZD- 1000 | HZD- 1000A | HZD- 1200 | HZD- 1200A | HZD- 1500 | HZD- 1500A | HZD- 1800 | HZD- 1800A | HZD- 2000 | HZD- 2000A |

| L | 2460 | 2950 | 2950 | 3330 | 3330 | 3500 | 3500 | 3500 | ||||||||

| W | 2410 | 2700 | 2860 | 3040 | 3140 | 3300 | 3460 | 3580 | ||||||||

| W1 | 1100 | 1440 | 1440 | 1440 | 1440 | 1550 | 1550 | 1550 | ||||||||

| W2 | 469 | 291 | 371 | 461 | 511 | 508 | 588 | 648 | ||||||||

| H | 3200 | 2800 | 3200 | 2800 | 3500 | 3100 | 3700 | 3300 | 3700 | 3500 | 4000 | 3600 | 4000 | 3700 | 4200 | 3900 |

| H1 | 1750 | 1350 | 1700 | 1450 | 1900 | 1550 | 1900 | 1650 | 1900 | 1700 | 2050 | 1750 | 2130 | 1830 | 2200 | 1900 |

| H2 | 1980 | 1580 | 1930 | 1680 | 2150 | 1800 | 2150 | 1900 | 2150 | 1950 | 2300 | 2000 | 2380 | 2080 | 2450 | 2150 |

| H3 | 2490 | 2090 | 2473 | 2223 | 2750 | 2400 | 2800 | 2550 | 2898 | 2698 | 3113 | 2813 | 3241 | 2941 | 3435 | 3135 |

| H4 | 2955 | 2555 | 3050 | 2800 | 3330 | 2980 | 3420 | 3170 | 3470 | 3270 | 3700 | 3400 | 3860 | 3560 | 3990 | 3690 |

| H5 | 740 | 340 | 653 | 403 | 755 | 405 | 740 | 490 | 688 | 488 | 723 | 423 | 741 | 441 | 740 | 440 |

|

混合轉速 Blending speed(Rpm) |

3~20 | 3~20 | 3~20 | 3~15 | 3~15 | 3~15 | 3~15 | 3~15 | ||||||||

|

凈負載 Net load(Kg) |

200 | 300 | 400 | 500 | 600 | 750 | 900 | 1000 | ||||||||

|

總功率 Total power(Kw) |

4.75 | 7 | 7 | 8.5 | 8.5 | 10.5 | 11.5 | 11.5 | ||||||||

|

機器重量 Machine weight(T) |

1.8 | 2.5 | 2.6 | 3 | 3.2 | 3.6 | 4 | 4.2 | ||||||||

所有參數僅作參考,視物料情況,本公司擁有變更權利,并不另行通知。

All datas are used for reference only. According to the condition of material, our factory has the right to change but not notice, pardon!

- 2025-11-21 > 力度干燥——四氧化鈷專用連續盤式干燥機工藝!

- 2025-11-20 > 力度干燥——熱效率拉滿,干燥零浪費!新一代噴霧干燥解決方案

- 2025-11-19 > 力度干燥——礦山 / 化工物料干燥,回轉滾筒更專業

- 2025-11-18 > 力度干燥——高濕高粘物料不粘壁,空心槳葉干燥一步到位

- 2025-11-13 > 力度干燥——耙式真空干燥機,膏狀 / 濾餅干燥神器!

- 2025-11-12 > 力度干燥——真空隔絕氧化!雙錐干燥機:守護熱敏物料原質原色!

- 2025-11-12 > 力度干燥——黃花菜烘干專用帶式干燥機!

- 2025-11-11 > 力度干燥——氧化鋁專用閃蒸干燥機

- 2025-11-10 > 力度干燥——錐形螺帶干燥機助力成品提質

- 2025-11-08 > 力度干燥——乳酸鈣壓力噴霧干燥機!